Ultrasonic Testing in Oil and Gas Infrastructure: Advantages, Future Expansion, and Safety Benefits

Introduction

The Oil and Gas industry is an essential sector that fuels the world’s energy needs. To ensure safe and efficient operations, the industry requires advanced inspection technologies. In this article, we will discuss the potential of ultrasonic testing in Oil and Gas infrastructure, focusing on its advantages, future expansion, and safety benefits.

Ultrasonic Testing in Oil and Gas Infrastructure

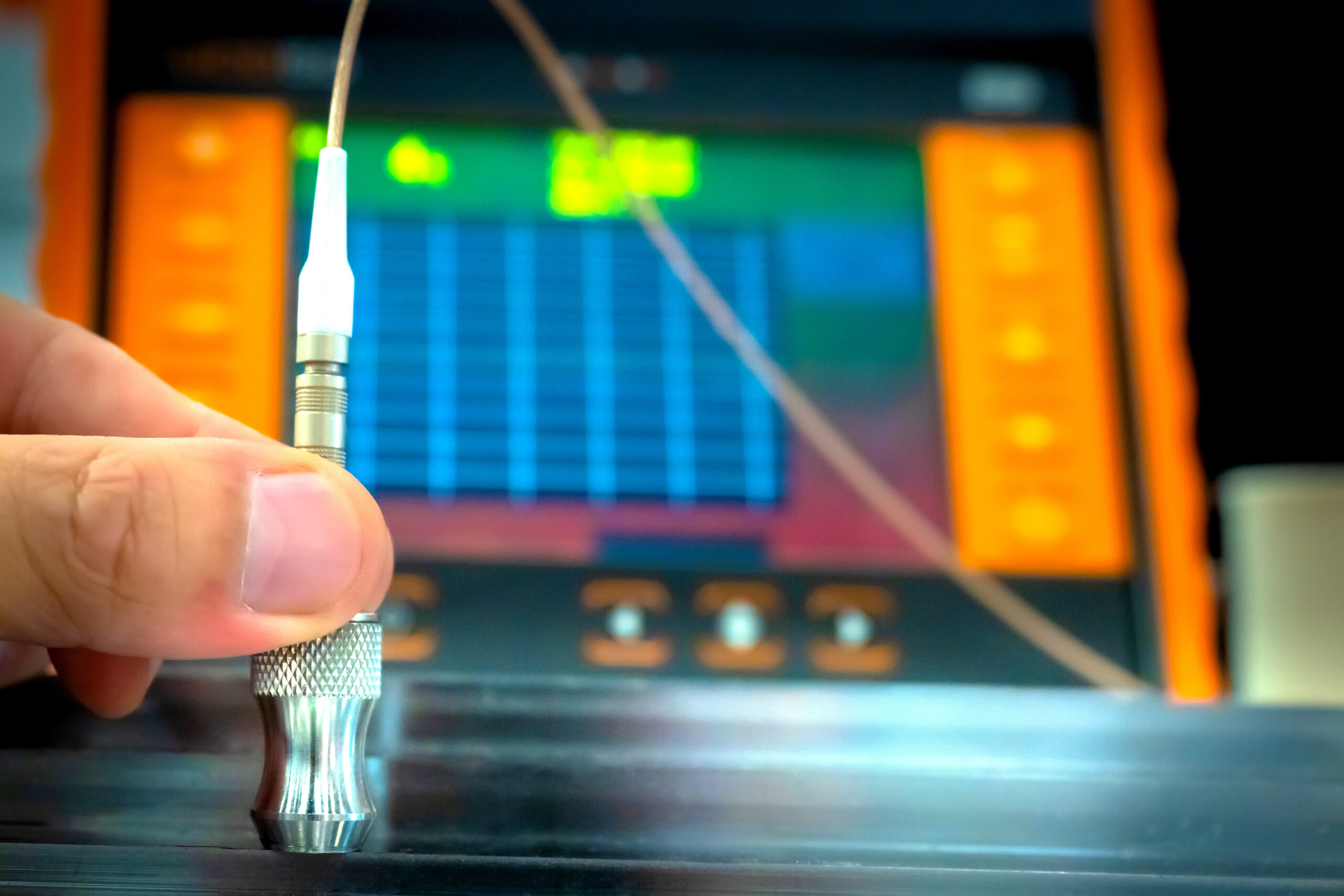

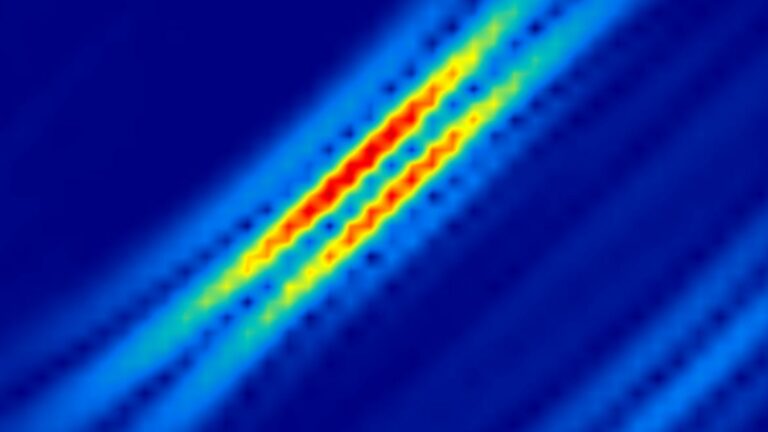

Ultrasonic testing is a non-destructive testing (NDT) method that uses high-frequency sound waves to inspect materials for cracks, corrosion, and other defects. This technology is highly effective in inspecting critical infrastructure in the Oil and Gas industry, including pipelines and storage tanks.

Advantages of Ultrasonic Testing

The benefits of ultrasonic testing are numerous, including its ability to detect and evaluate material defects quickly and accurately. By identifying defects early on, companies can take corrective measures to avoid costly repairs and prevent potential safety hazards. Ultrasonic testing is also highly flexible and can be used to inspect a wide range of materials, including metal, plastic, and composites.

Future Expansion Plans

As the Oil and Gas industry continues to evolve, there is a growing demand for more advanced inspection technologies. Ultrasonic testing is well-positioned to meet this demand, with the potential for future expansion in several areas.

One area of future expansion is in automated scanning technologies. By integrating ultrasonic testing with artificial intelligence (AI) and other advanced technologies, companies can create automated scanning systems that can inspect large areas of infrastructure quickly and accurately. This will significantly improve efficiency, reduce costs, and enhance safety.

Another area of potential expansion is in offshore infrastructure inspections. As offshore drilling becomes more widespread, the need for advanced inspection technologies that can operate in harsh environments increases. Ultrasonic testing is highly suited for this task as it can be performed remotely and can detect defects in hard-to-reach areas.

Safety Benefits

Safety is a critical concern in the Oil and Gas industry. Ultrasonic testing can significantly enhance safety by reducing the need for workers to be in potentially hazardous environments. The technology allows for remote inspections, minimizing the risk of accidents and injuries.

Conclusion

Ultrasonic testing is a powerful technology that provides numerous advantages to the Oil and Gas industry. With its potential for future expansion in automated scanning technologies and offshore inspections, ultrasonic testing can significantly enhance safety, improve efficiency, and reduce costs. As the Oil and Gas industry continues to evolve, ultrasonic testing will play a vital role in ensuring safe and efficient operations.