A Brief History of Ultrasonic Testing and its Evolution in the Oil and Gas Industry

Introduction

Ultrasonic testing has become an essential inspection method in various industries, including Oil and Gas. It is a non-destructive testing technique that uses high-frequency sound waves to detect and evaluate flaws in materials. In this article, we will explore the history of ultrasonic testing and its evolution in the Oil and Gas industry, providing insight into how this technology has developed and improved over the years.

The Early Days of Ultrasonic Testing

The development of ultrasonic testing can be traced back to the early 1920s when scientists began experimenting with high-frequency sound waves. In the 1930s, ultrasonic testing began to be used for the detection of cracks in metal parts. However, it was not until the 1950s that the technology became widely used for industrial inspections.

Ultrasonic Testing in the Oil and Gas Industry

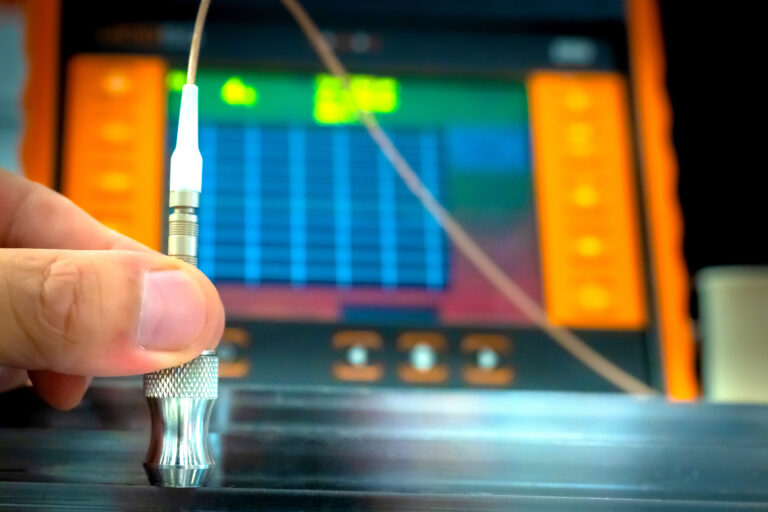

In the Oil and Gas industry, ultrasonic testing began to be used in the 1960s for the inspection of pipelines and storage tanks. At that time, the technology was limited to manual inspection methods, which were time-consuming and required highly skilled technicians.

In the 1980s, with the advancements in computing power and signal processing, automated ultrasonic testing began to be developed. This allowed for faster and more accurate inspections, reducing the risk of human error and improving efficiency.

The Evolution of Ultrasonic Testing

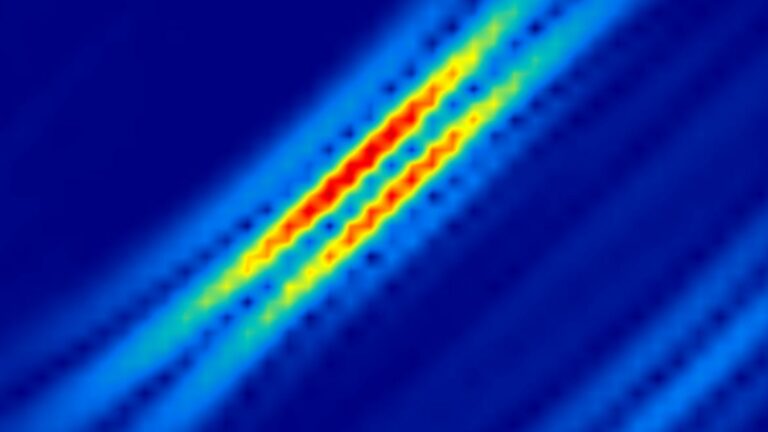

Over the years, ultrasonic testing has continued to evolve, with new techniques and technologies being developed to improve accuracy and efficiency. For example, Phased Array ultrasonic testing was introduced in the 1990s, allowing for more detailed inspections and reducing the need for multiple inspections. Time-of-Flight Diffraction (ToFD) was also introduced in the same decade, providing a more reliable method for detecting defects.

Today, the Oil and Gas industry continues to use ultrasonic testing for the inspection of critical infrastructure, including pipelines, storage tanks, and equipment. The technology has become more advanced and efficient, with the introduction of automated scanning systems and the integration of artificial intelligence and machine learning.

Conclusion

Ultrasonic testing has come a long way since its early days. It has become an essential inspection method in various industries, including Oil and Gas, and has undergone significant developments and advancements over the years. With the integration of new technologies, ultrasonic testing will continue to play a critical role in ensuring the safety and efficiency of operations in the Oil and Gas industry.