A Brief History of Phased Array Ultrasonic Testing in the Oil and Gas Industry

Introduction

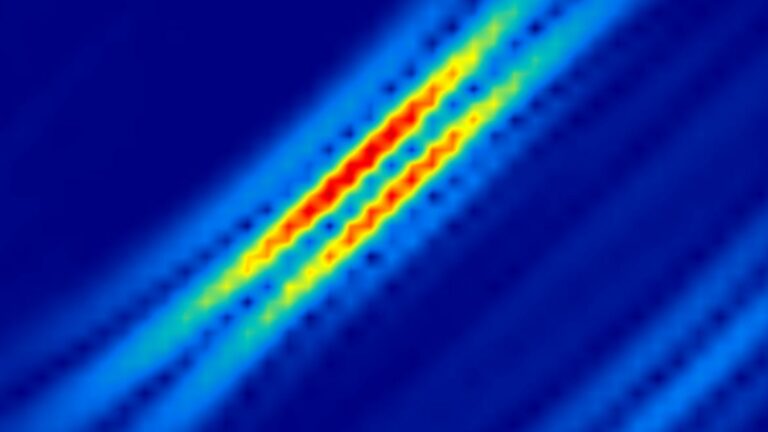

Phased Array Ultrasonic Testing (PAUT) is a non-destructive testing technique that has revolutionized inspection practices in the Oil and Gas industry. It uses advanced ultrasonic technology to provide detailed images of critical infrastructure, enabling precise detection and evaluation of material defects. In this article, we will explore the history of PAUT and its evolution in the Oil and Gas industry, providing insight into how this technology has developed and improved over the years.

The Early Days of PAUT

The development of PAUT can be traced back to the 1970s, when researchers began exploring the potential of phased array technology in ultrasonic testing. However, it was not until the 1990s that the technology became commercially available and began to be used in industrial applications.

PAUT in the Oil and Gas Industry

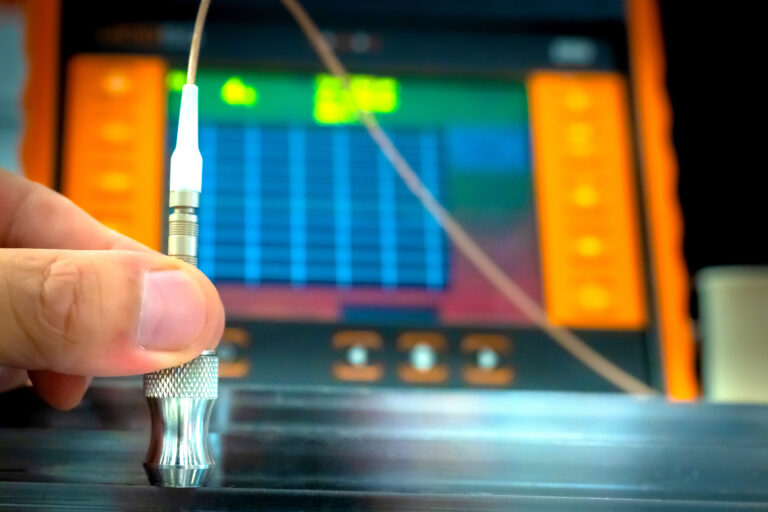

In the Oil and Gas industry, PAUT was first used in the 1990s for the inspection of pipeline girth welds. At that time, the technology was still in its infancy, and inspections were performed using manual scanning techniques. This was a time-consuming process that required skilled technicians and resulted in limited coverage of the inspection area.

Advancements in PAUT Technology

Over the years, PAUT technology has continued to evolve and improve, with new techniques and technologies being developed to enhance its capabilities. In the early 2000s, real-time imaging and data acquisition were introduced, allowing for faster and more accurate inspections. Later, the introduction of software algorithms for signal processing enabled improved defect detection and characterization.

Today, PAUT is widely used in the Oil and Gas industry for the inspection of pipelines, storage tanks, and equipment. Automated scanning systems have been developed, which can perform inspections quickly and accurately, reducing the risk of human error and improving efficiency.

The Benefits of PAUT

PAUT offers several benefits over traditional inspection methods, including improved accuracy, faster inspection times, and the ability to detect and evaluate a wide range of material defects. It also allows for the inspection of difficult-to-reach areas, reducing the need for equipment disassembly and minimizing downtime.

Conclusion

PAUT has become an essential inspection method in the Oil and Gas industry, providing a detailed and accurate evaluation of critical infrastructure. With the advancements in technology, PAUT has evolved into a powerful tool for detecting and evaluating material defects, and its use is expected to continue to grow in the future. As the Oil and Gas industry continues to evolve, PAUT will play a critical role in ensuring the safety and efficiency of operations.